Completing the largest modular fireproofing project in Australia.

The Northern Hospital in Epping is one of Melbourne’s major acute treatment centres. As an urgent response to recommendations from the Royal Commission into Victoria’s Mental Health System, The Victorian Government implemented a $492 million investment to deliver a new state-of-the-art acute mental health facility at the hospital.

Modscape, in collaboration with Lendlease, was appointed as the modular contractor to deliver the new mental health facilities. This unique modular project was the largest of its kind in the history of Australia. Our team was entrusted to supply and implement a multi-faceted passive fire protection solution, which spanned 165 modules. The job was also PROFINISH’s largest ever, but because of our size and scalability, we took it on with confidence.

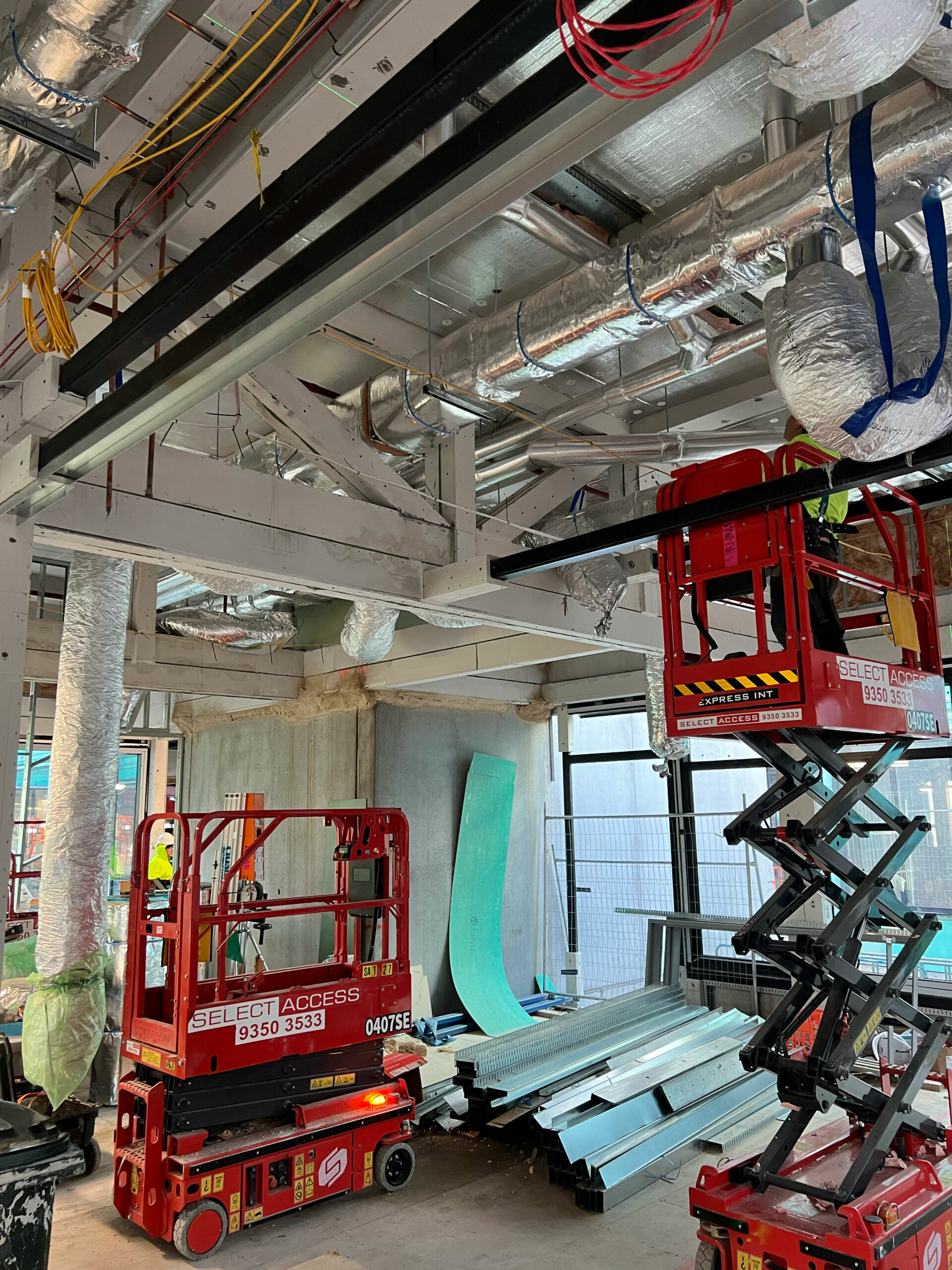

We assigned half of our specialists to an off-site space where they could work in a more controlled environment and fireproof the steel frames, as well as the flooring and the ceilings of each module. We needed to create a production line that started off-site and moved on-site.

Because it was a new building type, the project required an all new system. Our expertise meant that we could develop new installation methods and immediately apply them. We fast-tracked new testing methods and approvals with our suppliers and clients as well, and created an off-site way-of-working that streamlined the process and meant less waste of fireproofing materials.

Because of the unique nature of the job, the building phase required a much larger workforce. Access to supplies became a challenge, and we had to improvise on-the-go. Because this kind of project had never been undertaken, the usual processes no longer applied, and new processes had to be created and carried out the next day. This also meant that completely new methods of testing had to be carried out on all fireproofing products used as well.

Because of the size of our business, we were able to scale up from 40 specialists to 80 within a week. During the project, the fire retardant board supply diminished entirely. The team improvised by effectively completing the job using vermiculite fireproof spray and doubling up on thinner boards. The off-site environment was more controllable than the site itself. We took advantage of this by fireproofing the steel frames, checking and approving each module there, ensuring that the joins were left exposed, meaning that the reassembly of the modules was quicker and resulted in less wastage. Our expertise meant that we could establish a new workflow for the entire project, which we communicated to all other trades on-site to ensure a streamlined process throughout. All fireproofing products used on the job were successfully tested using all new methods.

The expertise of our team allowed us to be agile enough to come up with quick and efficient solutions to various challenges throughout the project. Considering the sheer size of the job, we were able to scale the size of our team up within a week, and developed new installation systems, which were implemented almost immediately.

Having completed the first job of its kind in Australia, we now have a wealth of knowledge and experience around modular builds and working in new ways. We’re very proud to have fireproofed the biggest modular build project in Australia.

We completed the 165-module job effectively and on time. The fireproof systems we implemented satisfied the requirements of the fire engineer after analysis of the project design and our work met the Performance Requirements stated in BCA.

Completing such a large and unique project has grown our experience in modular builds significantly. This means that we’ve increased our capabilities, and can be entrusted to work on any sized modular project in the future.

From standard jobs to the most complex and unique fireproofing requirements, the PROFINISH team has the expertise and knowledge to design the most effective passive fireproofing system for any project. Get in touch with one of our specialists today.

This was Australia’s largest modular fireproofing project.

Download this case study to share with your team. Learn more about our design, build and document process.

Enter your details to be sent a copy.